Collection: Molecular Distillation

Molecular Distillation is a type of short-path vacuum distillation, characterized by an extremely low vacuum pressure. It is a special liquid-liquid separation technology, which is different from the traditional distillation by boiling point difference separation principle, but by different substances molecular movement of the average free path difference to achieve separation.

How does it work?

Feed liquid is delivered from the a feed flask into a columniform evaporation section, getting heating, on the outside, (circulating hot fluid jacket type), and a slotted wiper mechanism forcing liquid around and downward in a thin film on the inside. In the center of the body is a wiped film evaporator with internal cooling condenser, providing a short path for vapor molecules traveling from the heated surface to the condenser surface.

During the itinerary downward, lighter (lower boiling point) fractions of the liquid begin to vaporize, move to the internal condenser and condense, falling down as a liquid into a vessel that catches and separates the distilled liquid (cannabinoid). Heavier residue material (CholorophyII, salts, sugars, heavy wax fractions) does not evaporate and instead travels through the still body and flows into a different receiver flask.

Application

Molecular distillation technique has been successfully utilized in many areas, such as foods, flavors, cannabis/hemp, garlic oil, cod liver oil and chemical and pharmaceutical industries.

In the cannabis distillation process it takes advantage of the melting points of cannabinoids. By using molecular separation, you can separate the THC/CBD from the terpenes, lipids, impurities and solvents, leaving you with an odorless and clear golden distillate.

Classification

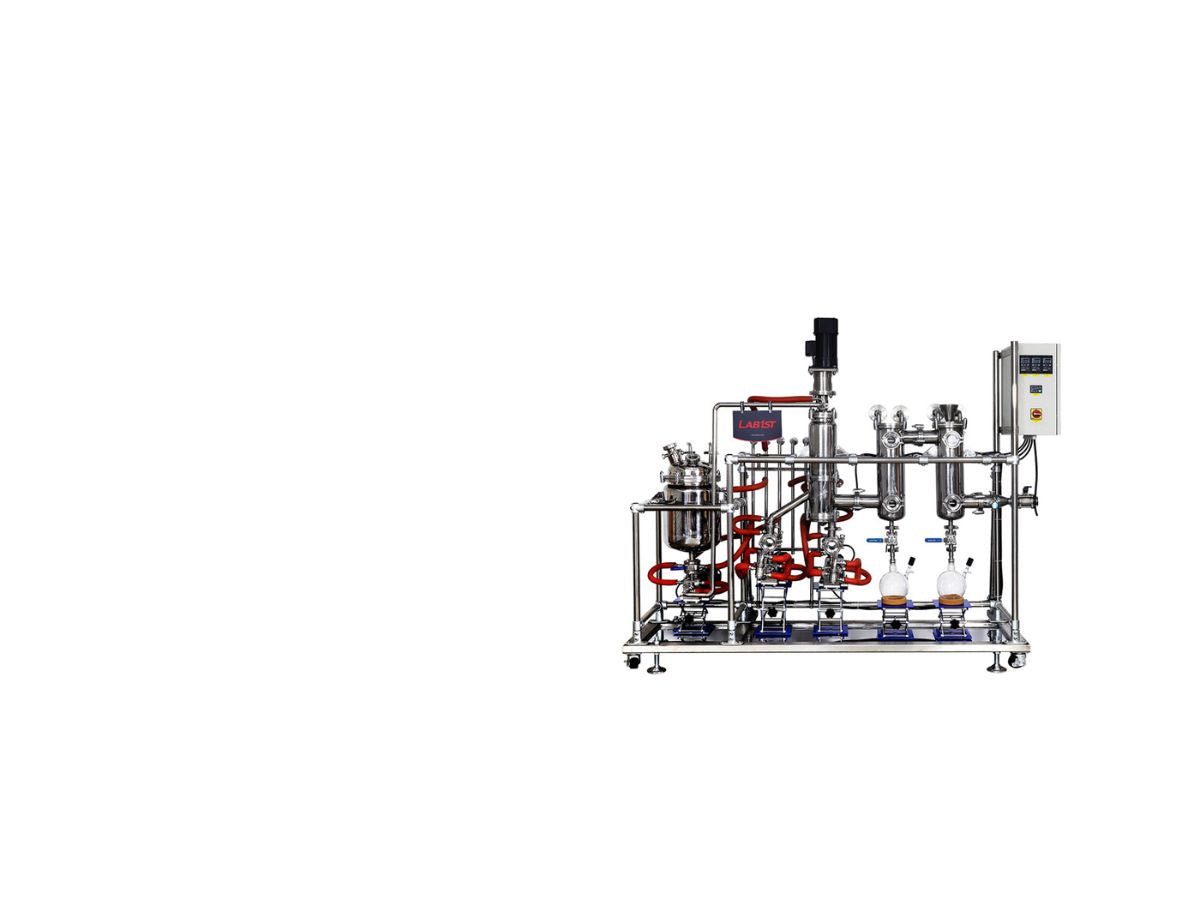

Stainless Steel Molecular Distillation

Stainless Steel Molecular Distillation

Stainless Steel Molecular Distillation

Stainless Steel Molecular Distillation Unit is a herb oil distillation unit with high distillation efficiency. Additionally, it is durable and can be used in cascade designs. The entire system is made of premium stainless steel material, making it so much more durable than the glass one. The throughput and feed rate capacity are dramatically promoted to an industrial use level.

We also offer industrial-scale molecular distillation units with higher yields to help you save even more time.

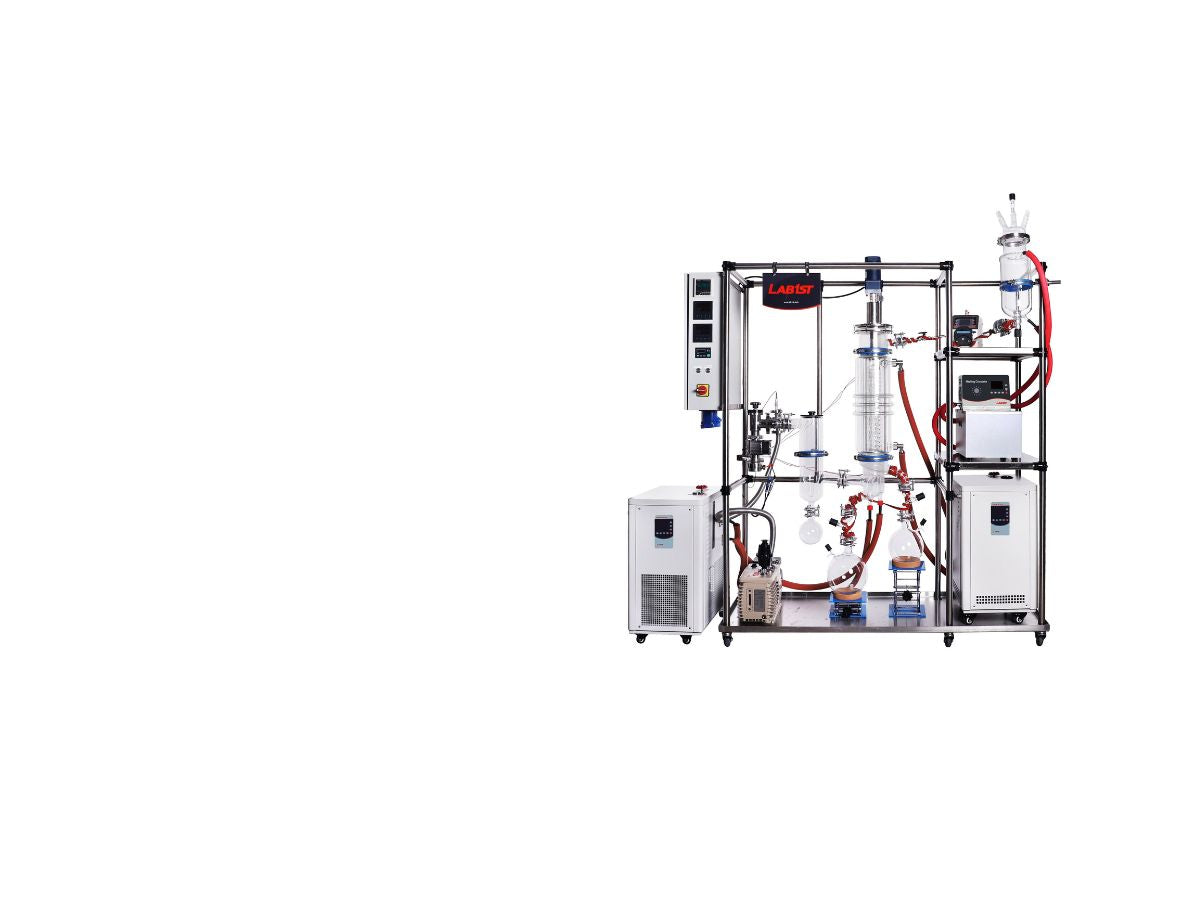

Glass Molecular Distillation

Glass Molecular Distillation

Glass Molecular Distillation

Glass Molecular Distillation is the best and gentlest thermal separation method for heat-sensitive materials. Widely used in vegetable oil, garlic oil, cod liver oil and chemical, pharmaceutical and other industries. Molecular distillation in glass uses durable borosilicate glass, which allows visual observation of the distillation process.

- Grease free high vacuum joints capable of as low as 0.1 Pa

- 45 degree chute on the strip controls residence time

- Precisely designed wiper structure for high stability in long-term operation

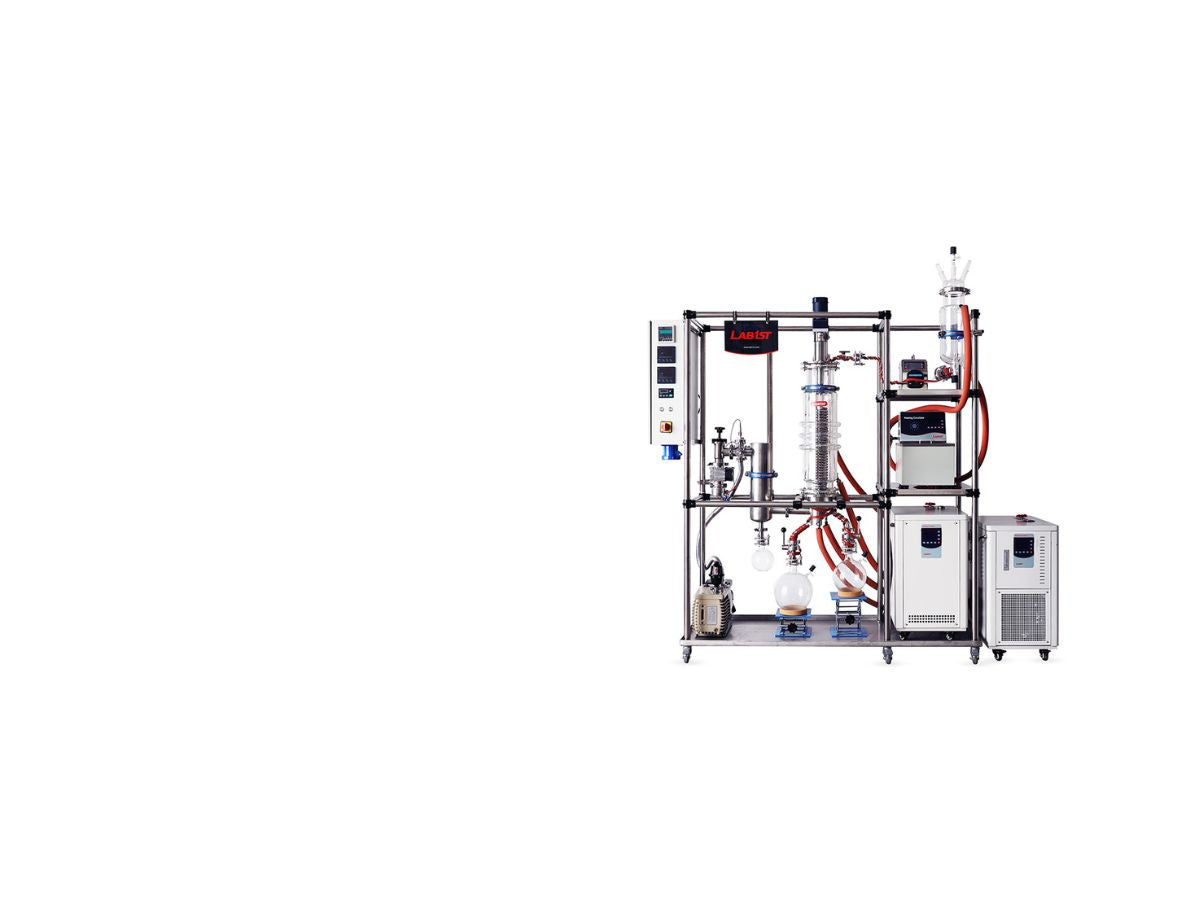

Hybrid Molecular Distillation

Hybrid Molecular Distillation

Hybrid Molecular Distillation

Hybrid Wiped Film Molecular Distillation is a NEW STYLE molecular distillation equipment that made by glass and stainless steel. It combines the advantages of the glass wiped film till and stainless steel molecular distillation such as process visibility, durable in use, high evaporator rate and so forth.

- All-in-one control panel design

- Grease free high vacuum joints capable of as low as 0.1 Pa

- 45 degree chute on the strip controls residence time

- Precisely designed wiper structure for high stability in long-term operation