Collection: Extraction

Centrifugal Extractor also known as a centrifugal contactor or annular centrifugal contactor uses the rotation of the rotor inside the centrifuge to mix two immiscible liquids outside the rotor and separate the liquids in the gravity field inside the rotor. In this way, the centrifugal extractor can continuously extract from one liquid phase to another. Lab1st LXJ-Series centrifuge extraction system (ethanol extraction system) can recover more than 97% alcohol from biomass, with the capacity from 7.5lbs per batch to 260lbs per batch.

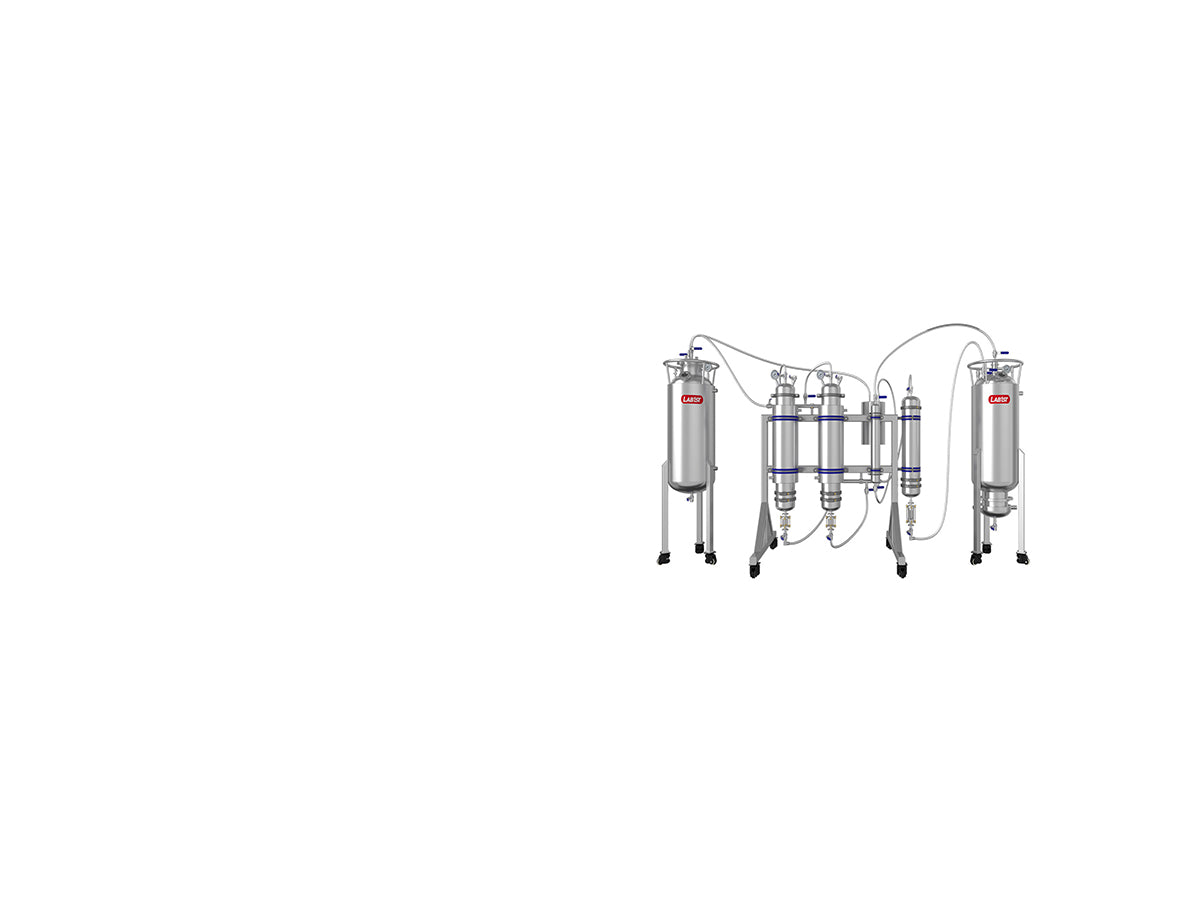

The Supercritical CO2 Extraction process creates phase changes in carbon dioxide utilizing temperature and pressure. CO2 is known as a “tunable solvent” making it extremely versatile for creating a multitude of end products by controlling temperature and pressure. These phase changes create an environment to drop out differing weights of components in the plant material. Lab1st SFE-series supercritical CO2 extractor can yield safer, cleaner, and purer oil from botanical plant material. It has been used in the food, cosmetics, and pharmaceutical industries.

Hydrocarbon Extraction is a type of extraction used to eliminate unwanted contaminants. Lab1st BHO extractor can run at low pressure, around 150 PSI (max. 200 PSI), with the capacity from 5lbs to 80lbs. It’s a very efficient and safe machine that can process material faster than CO2 extractors and at a fraction of the cost. We also provide extractors with ASME, GMP and other certification, so that you can have a different choice when getting economic benefits.

Vortex Trichome Separator also known as a hash washing machine, is a type of solventless, water-based separation equipment. It is primarily used to extract trichomes from plant material, particularly in the processing of trichome-rich plants.

Supercritical CO2 Extractor

Supercritical CO2 Extractor

Supercritical CO2 Extractor

We offer standard or customized models of different volumes and pressure ratings, with throughput from 5Ibs dry biomass per day to 15000Ibs per day to meet your needs. The lead time is usually within 1 month. Furthermore, we are also experienced in offering botanical extraction turnkey solutions (especially those of hemp and cannabis extractions), by commissioning 100+ supercritical co2 extractor systems around the world. If you have any other questions, please contact us.

Centrifuge Extractor

Centrifuge Extractor

Centrifuge Extractor

Centrifuge extractor is an industrial equipment that mainly used to extract target compounds from plant material with the help of different solvent, like ethanol, pentane, etc. Low temperature ethanol extraction is one of the most popular applications in hemp industry.

Lab1st LXJ-Series centrifuge extraction system (ethanol extraction system) can recover more than 97% alcohol from biomass, with the capacity from 7.5lbs per batch to 260lbs per batch. Equipped with the PLC controller, it’s perfect to work under programmable sequences, like soaking - extraction - separation and drying.

We also provide turnkey system including supporting chillers, transfer pumps, insulation jackets and all accessories.

BHO Extractor

BHO Extractor

BHO Extractor

Vortex Trichome Separator

Vortex Trichome Separator

Vortex Trichome Separator

The Lab1st Vortex Trichome Separator, also known as a hash washing machine, is mainly used in the extraction industry to produce high-quality hash and other trichome concentrates. This machine leverages cold water and mechanical agitation to separate trichomes from the plant matter efficiently and without the use of chemical solvents. This equipment can also be used in research institutions for plant separation experiments and in commercial production to extract active ingredients from other plants.

By employing this solventless water-based separation technology, producers can obtain high-purity extracts that meet market demands for natural and chemical-free products.

Working Principle

1. Cold Water Agitation:

-

-

- Plant material and cold water are placed into the machine’s mixing chamber. The use of cold water helps harden and separate the trichomes, making them easier to detach from the plant material.

-

2. Creating a Vortex:

-

-

- Once the machine is started, the agitator generates a strong vortex, causing the plant material to tumble and collide continuously. This mechanical action dislodges the trichomes from the surface of the plant material.

-

3. Separation and Collection:

-

-

- Trichomes are denser than plant residue and therefore settle at the bottom of the mixing chamber. Through a series of filters or screens, the trichomes are separated from the plant residue and collected in the filters or screens.

-

4. Extraction and Drying:

-

-

- The collected trichome suspension is filtered and washed multiple times to obtain pure trichome particles. Finally, these particles are dried to produce the final product, such as hash, loose resin, or other forms of concentrates.

-

Example Usage

Suppose an industrial facility is to produce hash. Here’s how the Lab1st Vortex Trichome Separator would be used:

-

-

- Preparation: Material are prepared and placed into the mixing chamber of the separator along with cold water.

- Agitation: The machine is started, and the agitator creates a vortex that causes the plant material to tumble and collide, dislodging the trichomes.

- Separation: The trichomes, being denser, settle at the bottom and are collected through a series of filters.

- Collection and Washing: The collected trichomes are further washed to remove any remaining plant residue.

- Drying: The washed trichomes are dried to produce the final product, such as hash or other concentrates.

-